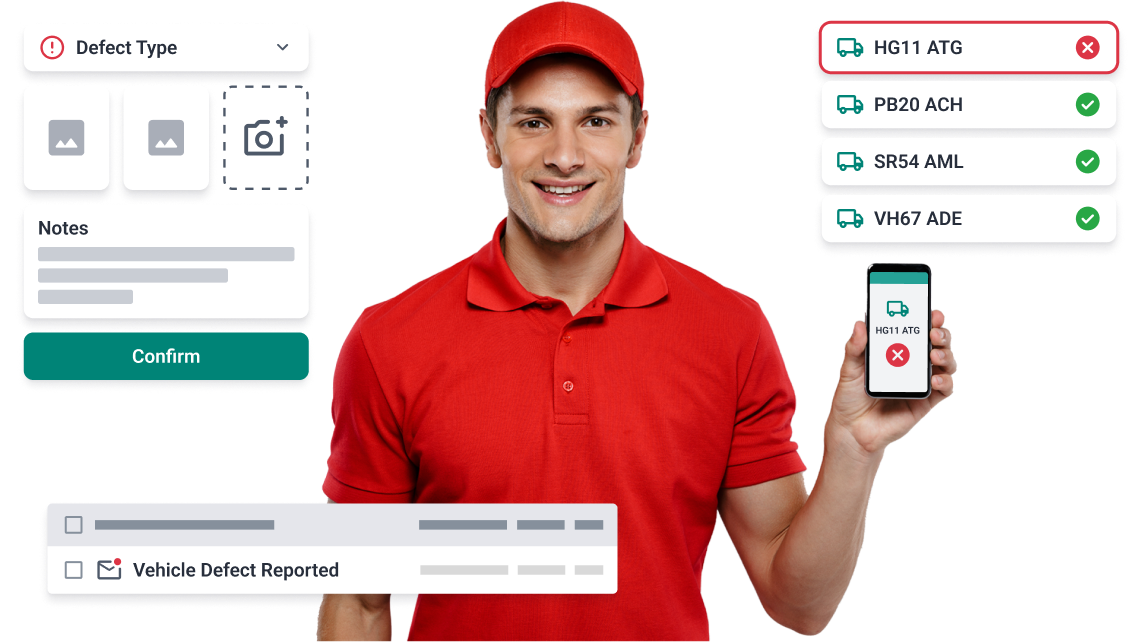

Defect Reporting Software

Report, record, and resolve vehicle defects quickly

Record vehicle defects, create a detailed audit history for each vehicle, and track defects through to resolution.

Defect reporting right in your driver’s pocket

Get instant notifications for new vehicle defects

Complete defect history against every vehicle

Defect Reporting features

Your toolkit for reporting defects

All the tools you need to effectively manage your defect reporting.

Defect reporting app

Custom defect types

Defect tracking

Vehicle defect history

Prevent vehicle usage

Major & minor defects

Instant defect notifications

Detailed information capture

Insights dashboard

Detailed analytics

Export your data

Multi-Lingual Transport Management System

Plan less, deliver more in your preferred language, across both the desktop application and ePOD app.

How it works

Efficient defect management from reporting to resolution

Discover, report, and resolve defects in Stream’s mobile app.

Create defect types

Report vehicle defects

Quickly resolve issues

Integrations

Integrate your existing systems

Use Stream as an approved ShipTrack carrier and pass tracking information to Amazon to keep your VTR scores above 95%.

Frequently Asked Questions

Yes, it does. Drivers can report defects and fill out the required fields in the Stream mobile app as part of the walkaround check process. They can even record detailed notes and use the phone camera to capture photos of every defect.

Yes, if the driver has no signal on their mobile device they can still complete vehicle checks and report defects. Any information captured will be passed back to Stream once their signal returns, and defect notifications will also be sent at this point.

You can use Stream to replace your paper vehicle defect book. Report defects in the mobile App, track defects from discovery to resolution, and build a detailed defect history for every vehicle, all in one place. You can even customise your settings to choose the information you want drivers to record about each type of defect.

Details of every defect reported are stored against the corresponding vehicles for 18 months, giving you the ability to build up a comprehensive vehicle defect history and audit trail for your entire fleet. You can also use Extended Data Retention to increase the amount of time that we hold this data for you.

Automatic alerts can be triggered when a defect is reported and the necessary steps can be taken to get the vehicle back on the road. Using the Stream mobile app to identify and report defects before they become a more serious issue can help keep those expensive repair costs down and keep your vehicles safe and out on the road.

Plan less, deliver more.

Slash your route planning time, cut your delivery costs and exceed your customer’s expectations.