Walkaround Checks Software

It’s time to ditch your paper-based vehicle walkaround checks

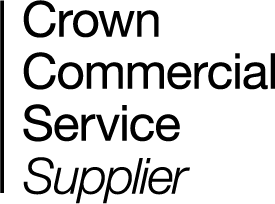

Complete vehicle walkaround checks and report defects in-app, and build a complete vehicle check history.

Capture vehicle walkaround checks (& record defects)

A detailed check history for every vehicle

Fully customisable walkaround check options

Analyse your vehicle check data to drive improvement

Walkaround Checks & Defect Reporting

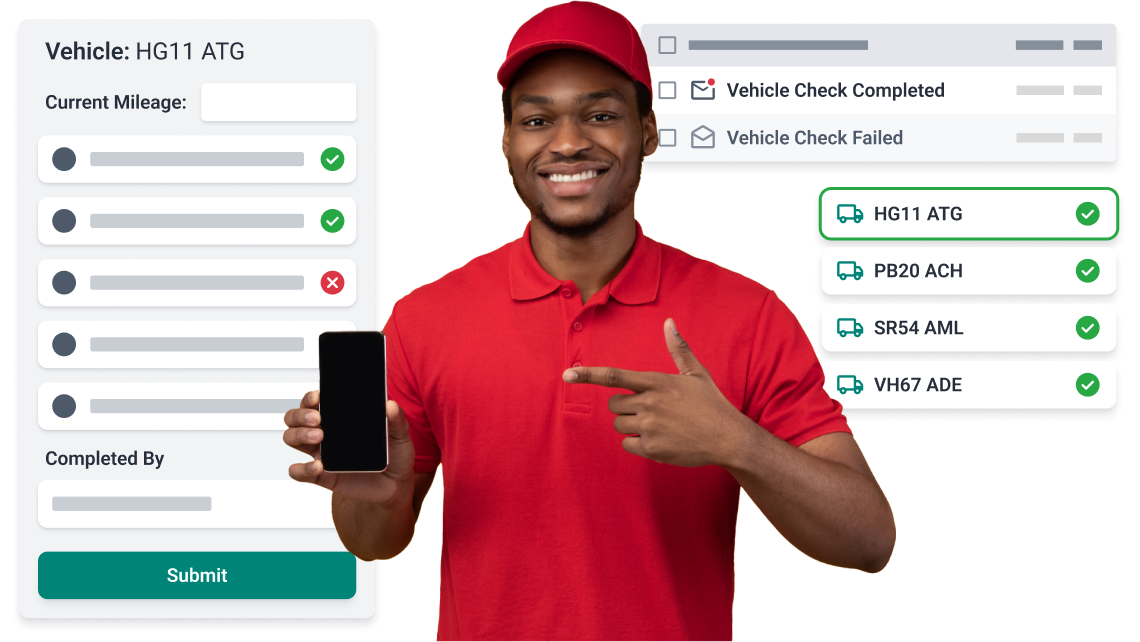

Looking for vehicle walkaround check & defect reporting software with a mobile app? Try our Stream Check Plan.

Walkaround Checks features

Helping keep your fleet safe, complaint, and roadworthy

Software and mobile app for drivers to complete their vehicle checks and build full an audit history.

Complete vehicle checks

Check history logged against each vehicle

Customise your checks

Create your own checks

Create check types

Check anything, not just vehicles!

Record details of accidents

Access vehicle checks at the roadside

Multi-Lingual Transport Management System

Plan less, deliver more in your preferred language, across both the desktop application and ePOD app.

How it works

Completing vehicle checks and reporting defects

Log into the app

Complete vehicle check

Check histories

Integrations

Integrate your existing systems

Use Stream as an approved ShipTrack carrier and pass tracking information to Amazon to keep your VTR scores above 95%.

Frequently Asked Questions

Vehicle walkaround checks are the checks your driver should carry out on their vehicle before setting off on any run, to ensure that the vehicle is safe and roadworthy. This is a legal requirement for HGV and PSV drivers, and best practice for van and LGV drivers. Daily vehicle walkaround checks should also incorporate a system of reporting and recording defects, including how they were rectified.

Yes! You can replace paper checklists with Stream. Drivers can complete their daily vehicle checks using the Stream mobile app on Android and iOS devices, and you can create and manage your vehicle walkaround checks in Stream using any web browser.

Details of every check completed are stored against the corresponding vehicles, giving you the ability to build up a comprehensive vehicle check history and audit trail for your entire fleet, for 18 months. You can use our Extended Data Retention add-on to increase the amount of time this data is held.

Yes! We have templates in our mobile app that are populated with the standard walkaround checklists recommended by the DVSA & RSA for different vehicle types, including HGVs, PSVs and vans. You can use these templates out of the box, or add custom checks relevant to your specific vehicles, business model, and industry.

Checks aren’t limited to vehicles. Create custom checks and check types (checklists) to check any equipment, plant machinery or PPE that your business uses. You can even create a custom check to use as an Accident Report to record the details of any incidents that occur out on the road.

You can export your vehicle walkaround checks reports and use them to measure performance and analyse your check data against your Key Performance Indicators (KPIs) and other business targets. You can access even more detailed data and reports about your vehicle checks using our Analytics add-on.

You can also export your vehicle walkaround checks reports as part of a compliance exercise, or an audit trail of walkaround checks that have been completed.

Stream’s walk around check app is not free, but we do provide a 30-day free trial so that you can test the application fully get a good feel for it. During the trial you will get access to all the features and will receive email support.

No, the Stream walkaround check app comes as part of the full fleet compliance software application. As well as the mobile app for drivers (where they can capture vehicle checks of any kind and report any vehicle defects), Stream Check comes with inspection and service scheduling and vehicle & driver management.

Plan less, deliver more.

Slash your route planning time, cut your delivery costs and exceed your customer’s expectations.