In logistics and transport management, keeping track of deliveries is crucial, not only for efficiency, but for building customer satisfaction.

One of the most effective ways to achieve this is through investing in barcode scanning technology.

By integrating barcode tracking into your delivery process, you can significantly enhance your logistics tracking, inventory tracking, and overall order management.

In this article, we’ll analyse the practical benefits of barcode scanning for delivery traceability and how you can implement it in your logistics operation.

Understanding barcode scanning in logistics

Barcode scanning technology is a method of encoding information about an item in a series of lines and spaces, which can be read by a scanner.

This technology has revolutionised the logistics industry by providing a simple, accurate way to track and manage inventory and deliveries as it passes through a supply chain.

The ability to quickly scan and access data ensures that stakeholders can maintain visibility over their fleet and inventory, turning from a reactive operation to a proactive operation.

What makes Stream stand out from other TMS Systems on the market is the ability to be able to track orders down to individual line item. This enables Stream to be extremely ‘granular’ which becomes even more important within high compliance industries (pharmaceutical logistics for instance) and / or when integrating with other back office systems – but more about that later on.

Why use barcode scanning for delivery traceability?

Enhanced delivery management

Barcode scanning simplifies delivery management by providing real-time data on the movement of goods.

Each item is assigned a unique barcode, which can be scanned at various points along the supply chain.

This creates a clear trail of information, allowing stakeholders to monitor the progress of an item as it passes through the supply chain and address any issues promptly.

Improving inventory tracking

Inventory tracking is a critical component of effective logistics management.

With barcode scanning, you can maintain an accurate inventory record, reducing the risk of overstocking or stockouts.

This accuracy is essential for maintaining efficient operations and ensuring that customer orders are fulfilled without delay.

Implementing barcode tracking in your logistics operation

Choose the right TMS system and equipment

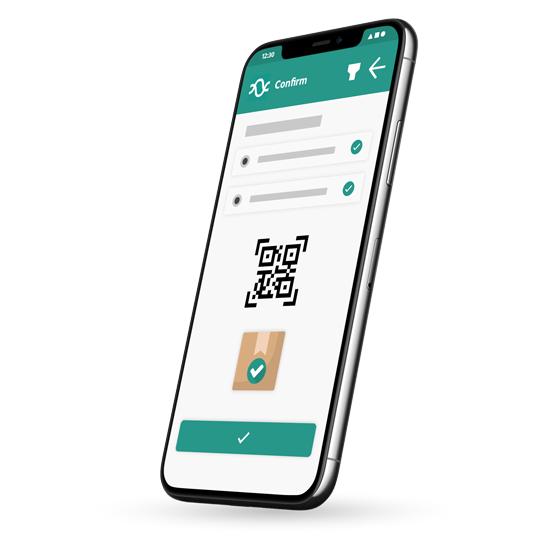

To integrate barcode tracking into your logistics operations, you’ll need to invest in the right TMS System and associated equipment.

This includes barcode scanners or rugged mobile devices, printers, and software that can process and store the data.

It’s important to choose equipment that is compatible with your existing systems and can handle the volume of data your operations generate.

Train your team

Implementing new technology requires a well-trained team.

Ensure your staff understands how to use the barcode scanning equipment and the importance of maintaining accurate records.

Provide training sessions and resources to help them become proficient in using the technology effectively.

Integrate with existing systems

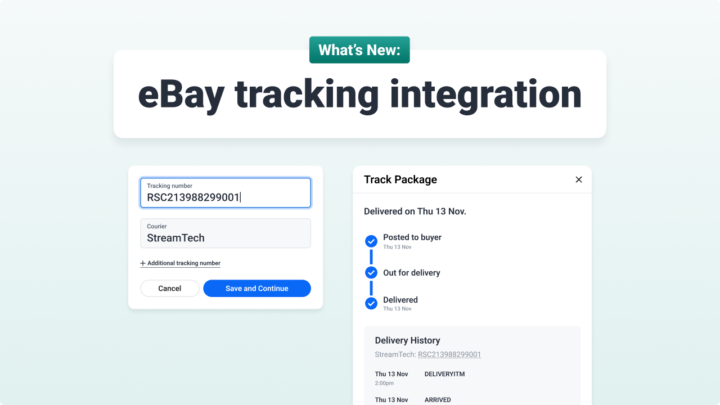

For seamless operations, integrate barcode tracking with your existing logistics or Transport Management System.

This integration allows you to centralise data collection and analysis, providing comprehensive insights into your delivery processes.

With a unified system, you can make informed decisions that enhance efficiency and customer satisfaction.

The Practical Benefits of Barcode Scanning

Increased accuracy and efficiency

Barcode scanning minimises human error, ensuring that data is accurately captured and processed.

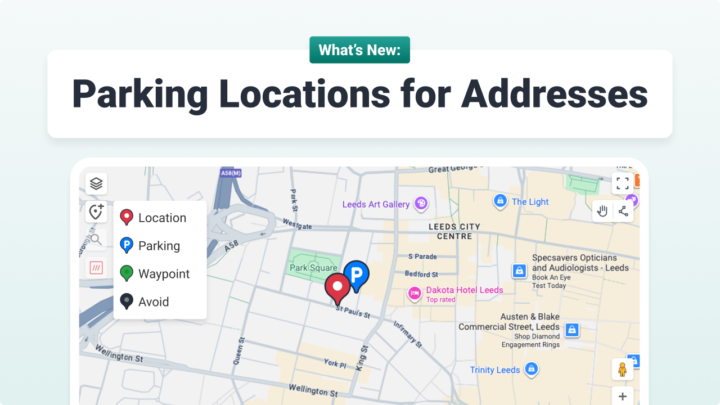

This accuracy leads to more efficient operations, as stakeholders can rely on the data collected to make informed decisions about inventory management, route optimisation, and delivery route scheduling.

Enhanced customer experience

Customers today expect timely and accurate deliveries. Barcode scanning provides the data needed to ensure that deliveries arrive on time and in the correct condition.

By keeping customers informed about the status of their orders, you can enhance their experience and build trust in your brand.

Reducing carbon emissions

Sustainability is a growing concern for logistics managers and sustainability officers.

By optimising delivery routes and reducing the number of unnecessary trips, barcode scanning can help lower carbon emissions.

Not to mention reducing your carbon footprint by using an all digital solution as opposed to a predated, paper-based solution to capture information.

This eco-friendly approach not only benefits the environment but also aligns with the sustainability goals of your organisation.

Conclusion

Barcode scanning for delivery traceability is a game-changer in the logistics industry.

It provides a reliable and efficient way to manage inventory, track deliveries, and enhance customer satisfaction.

By implementing this technology in your operations, you can achieve greater accuracy, efficiency, and sustainability.

Whether you’re a logistics manager looking to optimise your delivery systems, a sustainability officer aiming to reduce carbon emissions, or an e-commerce business owner seeking to enhance customer experience, barcode scanning offers a practical solution to meet your goals.