The world of wholesale and distribution is, quite literally, a complex web of moving parts.

Being able to get the right products to the right place at the right time throughout the supply chain is vitally important.

No matter if it’s B2B or B2C, buyers expect more than ever. Wholesalers and distributors are under increasing pressure to deliver products quickly and, where efficiency is king, accurately.

And when those products have higher levels of compliance associated with their distribution, the challenges are exacerbated.

Security, traceability, real-time data, and inventory visibility are essential for smooth operations in healthcare distribution centres around the world.

Fantasy becomes reality to meet today’s challenges

Imagine, for a moment, a world where:

- Every product can be traced back to its origin with a simple scan.

- You have real-time visibility into the location and status of your entire inventory.

- Theft and loss are minimised through secure, transparent systems.

- Customers have access to accurate delivery information and self-service tools.

This isn’t a futuristic fantasy.

From the moment items arrive at your warehouse or distribution centre, to their final delivery to the customer, you need to be able to track them and trace their journey through the system to ensure compliance, safeguard them from loss or theft and maintain security.

The importance of Barcode Tracking

Barcode tracking plays a pivotal role in ensuring traceability across your supply chain.

By assigning unique codes to each product, wholesalers and distributors can, for instance, easily track items as they move from manufacturer to warehouse and then onto and off delivery vehicles to the end customer.

This not only helps with efficient inventory management, improves operational efficiency, but also minimises losses and errors, which can have a direct impact on the bottom line.

The global market for track and trace solutions was valued at over $4 billion in 2023. It is expected to exceed $11 billion by 2032 [Source: Track and Trace Solutions Market Size].

And the driver for that growth? An increasing demand for transparency across the supply chain and regulatory compliance.

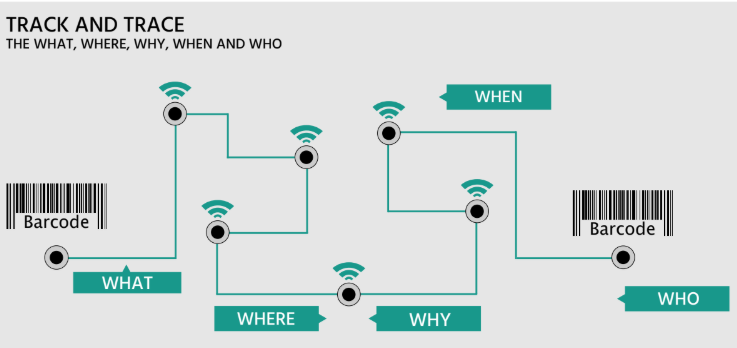

Tracking the What, Where, Why, When and Who

When we go back to the tenets of a smooth healthcare distribution operation mentioned earlier (security, traceability, real-time data, and inventory visibility) there are many questions to consider.

For example we should consider the questions of “What is this item?” and “Where has this item come from?” and “Where is it going?”

Importantly, from a traceability perspective, we can then start answering the questions of “Why is it here?”, “When does it need to leave?” and “Who is handling it?”

What?

It is easy to convince ourselves that we know what everything is in our supply chains.

Sadly, this is not always the case.

As with many other areas of business, your supply chain is only as good as the data you collect, so if you are unclear exactly what things are when they arrive, it’s inevitable that problems will occur later down the chain.

Scanning an item’s barcode on arrival is the first step towards creating a fully transparent chain. Knowing what each item is from the moment it arrives means that you can start from a position of control.

Where?

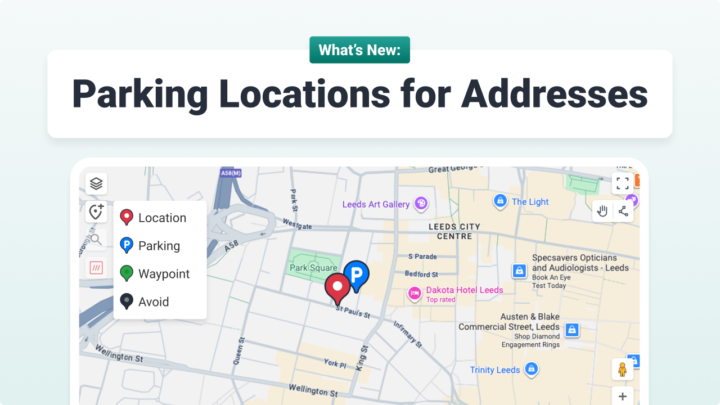

Most organisations will know where they have stored items, but few have truly got to grips with every aspect of ‘Where’ in their supply chain.

Providing key staff and stakeholders with access to important data is essential. This data includes information about where items come from, where they are going, and where they are stored. This approach creates transparency and enhances control over logistics operations.

When your warehousing, inventory, and other back office systems work together, your supply chain becomes proactive, interactive and more communicative.

And, at that point it can better support your customers.

Why?

How often do you stop and ask ‘Why’ an item is in your supply chain?

Why do we have it? Is it the correct item? Who has sent it? What happens next?

Not knowing why you have certain goods affects your operational efficiency and effectiveness. It can also harm the integrity of your supply chain.

Space given over to items that are in your warehouse but should be elsewhere costs you time and money.

With a clear, transparent flow of goods and data, you will have complete control over your entire supply chain.

When?

When did this arrive in my warehouse? When is it leaving? When will it arrive with the customer?

The timing of when an item becomes your responsibility is crucial. It is also important to know when the item will be delivered. These questions are central to all distribution operations.

An efficient operation keeps items for the shortest time and delivers them to customers as quickly as possible.

Who?

The question of ‘who’ goes further than just understanding who is the final recipient or who produced the goods in the first place.

It is important to know who has interacted with each item. This includes tracking the hands it has passed through and identifying the people responsible for handling those items.

By employing robust hand-held devices for barcode scanning, we can enhance our tracking capabilities. These devices are integrated with our back office systems.

As a result, we can monitor every individual who has interacted with each item throughout its journey.

Taking advantage of the What, Where, Why, When and Who

Central to all good distribution strategies sits an understanding of how to manage the ‘What, Where, Why, When and Who’.

Businesses who have successfully achieved this have three areas of focus in common:

- Implementation and application of barcoding and scanning

- Warehouse, inventory and logistics integration

- Use of mobile devices.

Once these areas are in place, businesses can expect the following benefits:

Improved accuracy & operational efficiency

- Reduced human error: Barcodes eliminate the need for manual data entry, which can be prone to mistakes.

- Real-time tracking: Barcodes provide instant access to information about items, allowing for efficient tracking and management.

- Faster processing: Scanning barcodes is much quicker than manually entering data, speeding up processes like inventory checks and checkout.

Enhanced Inventory Management

- Accurate stock levels: Barcodes enable businesses to maintain precise inventory counts, preventing stockouts or overstocking.

- Efficient stock rotation: Barcode tracking can help identify and manage items with approaching expiration dates, reducing waste.

- Improved order fulfilment: By knowing the exact location of items, businesses can fulfil orders more efficiently.

Cost Savings

- Reduced labour costs: Barcode systems can automate tasks, reducing the need for manual labour.

- Improved inventory accuracy: Accurate inventory management can help prevent losses due to theft, damage, or obsolescence.

- Optimised logistics operations: efficient tracking can lead to cost savings in transportation and storage.

Increased Security

- Improved asset tracking: Barcodes can help track and manage valuable assets, reducing the risk of loss or theft.

- Chain of custody: Barcodes can create a clear record of an item’s history to ensure product safety and prevent fraud. This is vital for security and compliance.

Better Customer Service

- Faster checkout: Barcode scanning can speed up the checkout process, improving customer satisfaction.

- Accurate pricing: Barcodes ensure that customers are charged the correct price for items.

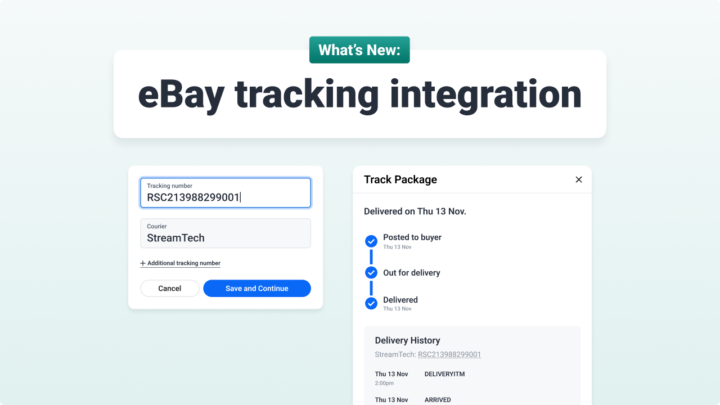

- Real-time updates: Barcode tracking can provide customers with real-time updates on their orders. Failure to provide this information can lead to a negative customer experience and lower retention rates.

Technology to Support Traceability

For barcode scanning and inventory tracking to be effective, wholesalers and distributors need technology to store, view and manage the information from the scan – this is typically referred to as an inventory or warehouse management software, such as the system offered by our technology partner Access Mintsoft.Mintsoft enables barcode scanning from both the desktop version of its software and via its android mobile app – giving operatives the ability to use it from anywhere in the warehouse, with real-time inventory sync.

With its ability to hold crucial stock information such as batch numbers and expiration dates, alongside it tracking every action performed, traceability of inventory has never been easier. Find out more about Access Mintsoft.